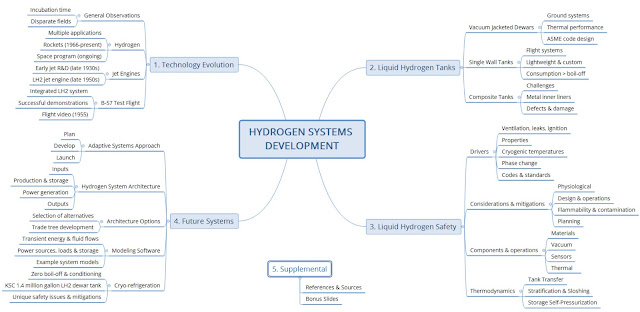

Technological evolution often requires decades of incubation and advancement in a variety of fields before large scale commercial adoption is achieved. Hydrogen has followed these trends since its discovery in the late 1700’s and subsequent application for wide ranging industrial uses. Liquid hydrogen (LH2) has been in routine and continuous use in the space program since the early 1960’s. However, many are not aware that its roots in aerospace trace much further back in aviation to the initial jet engine research and development in the late 1930’s; and later with successful flight demonstrations of a liquid hydrogen fueled jet engine in the mid-1950’s.

Modern LH2 systems make use of vacuum jacketed dewars for long term storage on the ground. Flight vehicles have used single wall tanks with foam insulation which significantly reduces mass but is only viable if the consumption rate in flight is greater than the boil-off venting required to meet tank pressure constraints. Composite LH2 tanks of various types (with or without metal inner liners) have been attempted over the years with mixed success and are still under development.

Safety with LH2 is a paramount priority. Key drivers are related to hydrogen’s properties, LH2 cryogenic temperatures, and liquid-vapor phase change within the system. Many legacy standards, codes and guidelines exist for LH2, and many more are in active formulation or revision. The three primary mantras to remember when designing and operating hydrogen systems is: 1) provide ventilation, 2) prevent leaks, and 3) eliminate ignition sources. Understanding the thermodynamic behavior of LH2 systems during various operations is also critical.

The development of future hydrogen systems can be optimized using an adaptive systems approach that treats hydrogen as a critical enabler in an overall system architecture rather than simply a commodity fuel. Selecting architecture options permit trade studies of candidate system concepts that can be assessed on the basis of technical, economic, environmental impact, and other key performance metrics. The end result is the ability to optimize systems for a multitude of hydrogen applications that can then be modeled, simulated, developed, assembled, and put into operation. Further, the proven ability to eliminate boil-off losses in LH2 systems - and provide better performing and sustainable propulsion and power relative to legacy fossil fuel systems - will play a key role in the global transition to hydrogen

See slide package here: https://drive.google.com/file/d/13CYhHxrRy8CcnwLKUjnatyY4ZiamiNst/view

Matt Moran is the Managing Member at Moran Innovation LLC, and previous Managing Partner at Isotherm Energy. He's been developing power and propulsion systems for more than 40 years; and first-of-a-kind liquid, slush and gaseous hydrogen systems since the mid-1980s. Matt was also the Sector Manager for Energy & Materials in his last position at NASA where he worked for 31 years. He's been a cofounder in seven technology based start-ups; and provided R&D and engineering support to many industrial, government and research organizations. Matt has three patents and more than 50 publications including the Cryogenic Fluid Management report series. More about him can be found here.