"Huge amounts of uncounted emissions of highly warming greenhouse gas methane are being released by "super-emitters" all over the world, satellite observations reveal.Scientists have only recently worked out how to detect methane emissions from space, but what they have seen since has taken them by surprise. The greenhouse gas, which is 80 times more potent than carbon dioxide, is leaking from gas pipelines, oil wells, fossil fuel processing plants and landfills all over the world. It is frequently released through negligence and improper operations; the emissions, in many cases, are not accounted for in mandatory greenhouse gas inventories.'We see quite a lot of those super-emitters,' Ilse Aben, senior scientist at the Netherlands Institute for Space Research (SRON) told Space.com. 'These are large emissions, and we see a lot of them on the global scale — much more than we had expected."Source: "Satellites discover huge amounts of undeclared methane emissions", Tereza Pultarova, Space.com, published Nov 15, 2021.

The above excerpt, as alarming as it sounds, is only part of the existential threat that greenhouse gas (GHG) emissions represent. Every life form on earth is being affected by GHG emissions, and the effects are growing by the day.

We are being stalked by an extinction-level monster of our own making. It has been increasing environmental temperatures, raising sea levels, driving ocean acidification, causing more severe weather patterns, increasing wildfires, worsening droughts in some regions, and giving rise to more flooding in others.

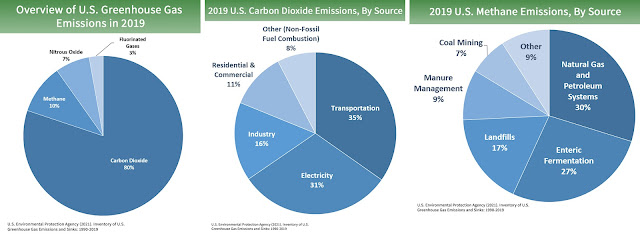

Consider the GHG emissions estimates shown at the top of this post from the U.S. Environment Protection Agency (EPA). 92% of U.S. carbon dioxide emissions come from the burning of fossil fuels; and 37% of methane emissions come from coal mining, natural gas and petroleum systems (e.g. leaks). Note that this latter figure is likely much higher due to unreported emissions based on recent satellite data.

But Wait, There’s More

When I was recruited by NASA in 1985 it seemed like a world away from the coal-fired power plant where I had previously worked. I would go on to develop power and propulsion technologies and systems for various rockets, aerospace vehicles, and spacecraft over the next several decades.

However, my first assignment was designing combustion experiments for basic research on the space shuttle. The principal investigator on one of those experiments was an internationally renowned combustion expert from Princeton University. When we started observing unexpected soot formation during one of the tests, he made the following remarks (paraphrased from memory):

"Soot is an interesting topic. There is a soot particle size above which the respiratory system in a healthy person filters it before reaching the lungs. At a smaller size, the soot particle is inhaled into the lungs but can also be exhaled out. Between those two size thresholds are soot particles that don't get filtered and can't be exhaled. These become trapped in the lungs. Diesel soot falls into this category. That's why the exhaust outlets of diesel vehicles are generally positioned so high..."

The casual manner in which he delivered this information stunned me. Stammering in response, I asked "You mean to tell me that diesel soot I've breathed in during my life so far, and all that I'll inhale the rest of my life, may be permanently trapped in my lungs?" "That's right", he matter-of-factly responded.

We’ve Played This Game Before (Many Times)

Public safety always takes a back seat to profit. It doesn't matter what industry, which company, or who is involved. If there are vested interests making substantial revenue from a product that results in severe health risks, heavy lobbying and campaign contributions will always delay accountability for decades.

It seems to be a consistent pattern of our species that we sacrifice our own collective well being in the name of industrial progress. Asbestos, coal dust, dioxins, lead, mercury, nuclear radiation exposure, oil spills, particulate emissions, PCBs, pharmaceuticals, plastic waste, sulfur emissions, VOCs, … the list goes on and on. GHGs are just another variation on the theme.

Previous cycles of this form of tragedy of the commons have resulted in untold disease and death since the dawn of the industrial revolution. This time, however, the impact is global in reach and catastrophic in consequence for all of us.

In This Corner Weighing in at One Atomic Mass Unit...

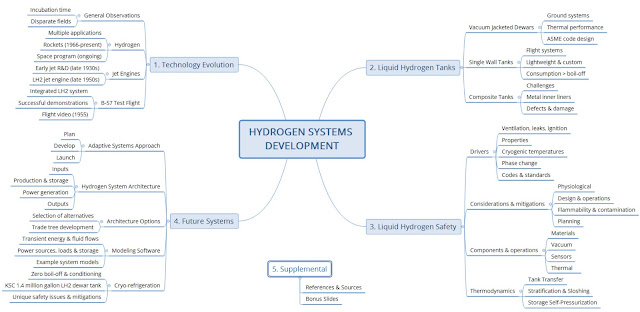

After my brief stint in low gravity combustion research, I began developing, testing and deploying liquid hydrogen technologies and systems starting in the mid-1980s. This would become a core part of my career for the next 35 years, and continues to be so.

Most of those liquid hydrogen projects were related to aerospace, defense and energy systems. More recently, this has expanded to transportation vehicles and infrastructure systems. In the early days, the hydrogen community was very concentrated and technically proficient. This has changed considerably in the last few years as mentioned in a previous post.

Transitioning to hydrogen represents one of the fundamental solutions to the GHG emission problem, along with addressing the plethora of public health impacts of fossil fuel usage. Large scale electrolysis plants are coming online at a rapid clip to cleanly produce hydrogen from water using renewable energy resources.

These renewable resources can be from overgeneration capacity; dedicated microgrids; and/or from regions where solar, wind, water, or geothermal energy far exceed the regional electrical demand. The latter case represents a lucrative opportunity for some regions to be primary exporters of hydrogen to the regions with high electrical demand but limited renewable resources (e.g. the recent trade agreement involving Australia exporting liquid hydrogen to Japan).

When hydrogen is fed to a fuel cell for electrical generation, water vapor is the only emission. When burned in a turbine or engine, water vapor and NOx are the only emissions. Note the NOx is a byproduct of all high temperature combustion processes and can be reduced by a variety of methods.

Hydrogen released into water or air readily combines with available oxygen and hydroxides to form water vapor. Preferable to releasing it, however, leaked or vented hydrogen can be used in fuel cells for auxiliary power. It can also be recaptured and compressed or liquefied to minimize waste. If release of hydrogen in air is absolutely necessary for a given system operation, it can also be flared to mitigate unwanted local concentrations.

Made from water with renewable energy. Returned to water in a fuel cell or combustion process. Hydrogen is the infinity fuel for our sustainable future. In future posts, I'll delve more deeply into the details of our shared path to the liquid hydrogen era.

Matt Moran is the Managing Member at Moran Innovation LLC, and previous Managing Partner at Isotherm Energy. He's been developing power and propulsion systems for more than 40 years; and first-of-a-kind liquid, slush and gaseous hydrogen systems since the mid-1980s. Matt was also the Sector Manager for Energy & Materials in his last position at NASA where he worked for 31 years. He's been a cofounder in seven technology based start-ups; and provided R&D and engineering support to many industrial, government and research organizations. Matt has three patents and more than 50 publications including the Cryogenic Fluid Management report series. More about him can be found here.

(TM).jpg)